We are utilizing our solution dispersions of 2D layered materials and other nanomaterials for additive manufacturing platforms, specifically ink-jet printing and 3D printing for flexible electronics, forming composites and biosensing devices.

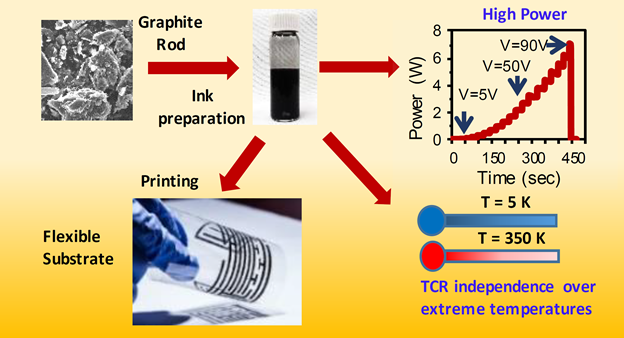

An example of devices for flexible electronics: A high-power graphene resistor

In our recent work that appeared in 2D Materials journal (IOP), we reported on using additive manufacturing techniques for 2D layered materials, such as ink-jet printing, which is a facile approach for incorporating these exotic materials into device platforms for flexible electronics. In this work, graphene ink formulations were successfully utilized toward the design and fabrication of high-power resistive structures that are printed on both rigid and flexible substrates and have the potential to deliver close to 10 W of power. A near-flat, negative temperature coefficient of resistivity (TCR) is measured with an activation energy Ea ~ 2.4 meV for electron hopping, which is 100× lower compared to Ea values for high TCR materials. The TCR and Ea values are amongst the lowest reported for 2D layered material systems. The thermal-invariance of resistivity for such high-power graphene printed resistors is attractive for applications, for example to provide a stable heating source for flexible electronics over extreme thermal environments. The transport characteristics of the ink-jet printed features is modeled as a composite structure in order to explain the thermal response which appears to be mediated via defects in the sonicated graphite, and correlates well to inferences made from Raman spectroscopy and transmission electron microscopy analysis conducted on the printed graphene structures. In order to fabricate such functional structures with ink-jet printing, the active nozzle number, printing passes, and annealing conditions are shown to play an important role to determine line resolution, and also dictate the morphological and electronic transport characteristics of the printed graphene features.

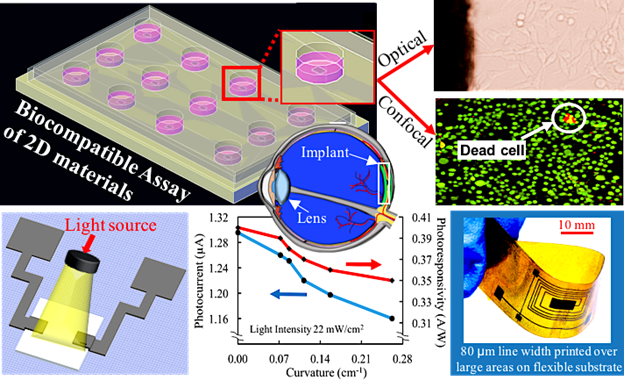

Example of devices for bio-related applications: A biocompatible MoS2 photodetector

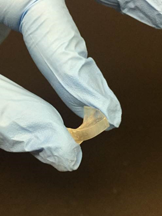

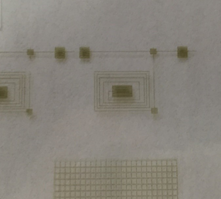

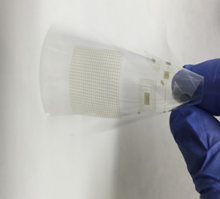

In our recent work that appeared in Nature npj 2D Materials and Applications journal, an inkjet printed, biocompatible, heterostructure photodetector is described that was constructed using inks of photo-active molybdenum disulfide (MoS2) and electrically conducting graphene which facilitated charge collection of the photocarriers. The importance of such devices stems from their potential utility in age-related-macular degeneration, which is a condition where the photosensitive retinal tissue degrades with aging, eventually compromising vision. The absence of effective therapeutic remedies for patients with this disorder has motivated the development of such devices to restore some degree of visual function. Inkjet printed, flexible prosthetic devices offer design simplicity where additive manufacturing can enable large format, low-cost arrays. The biocompatible inkjet printed two-dimensional heterojunction devices were photoresponsive to broadband incoming radiation in the visible regime, and the photocurrent Iph scaled proportionally with the incident light intensity, exhibiting a photoresponsivity R approx. 0.30 A/W. This is 1000 times higher compared to prior reports, and detectivity D was calculated to be ~3.6 × 10^10 Jones. Strain-dependent measurements were also conducted with bending, indicating the feasibility of such devices printed on flexible substrates. Drop cast and printed CT-MoS2 inks were characterized using techniques, such as Raman spectroscopy,photoluminescence measurements and scanning electron microscopy. Both mouse embryonic fibroblast and human esophageal fibroblast were used for the biocompatibility analysis for inks drop cast on two types of flexible substrates, polyethylene terephthalate and polyimide. The biocompatibility of inks formed using two-dimensional graphene and MoS2 on polyimide

substrates was extremely high, in excess of 98% for mouse embryonic fibroblast. To learn more about this work, we refer you to our publication on this work.

Other bio-related applications of our devices include forming biosensors and devices for implantable electronics.

Our lab is equipped with a material printer where we have printed a wide range of 2D layered material dispersions over a range of substrates, including flexible, transparent and biocompatible substrates.

Material Printer used for Additive Manufacturing

We also have efforts in creating hybrids of 2DLMs with organic materials for composites and opto-electro-mechanical and strain-based sensors. These materials are formed into composites which are then 3D printed to form devices for various applications.